TYCOR®

TYCOR®:

An Engineered Fiberglass Core

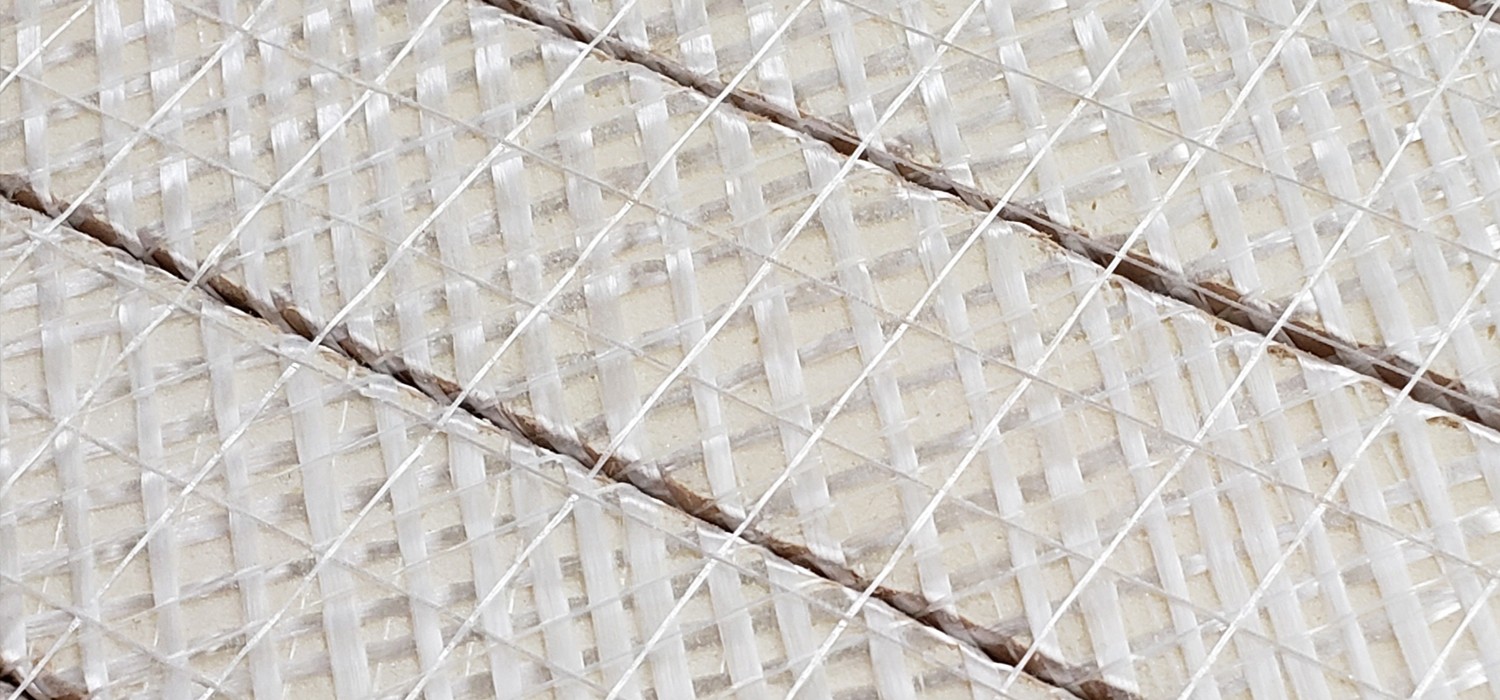

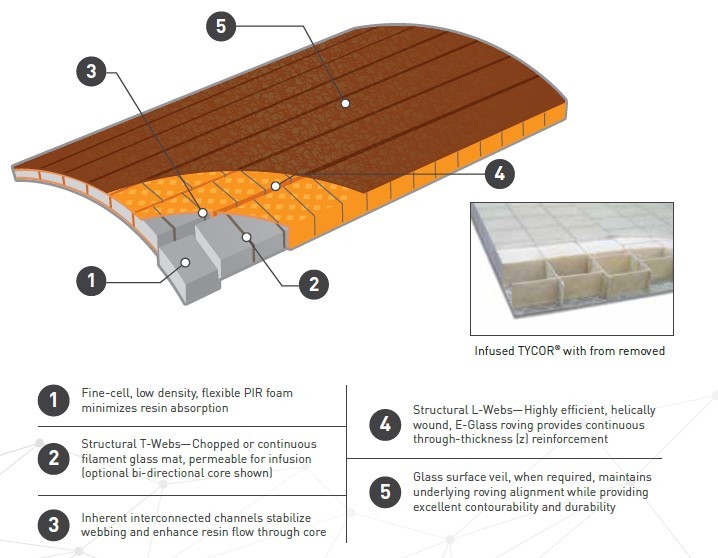

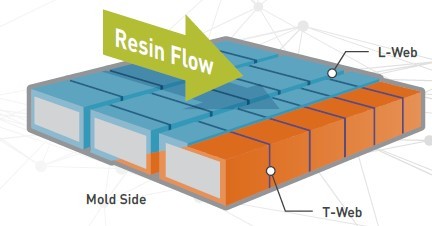

TYCOR® provides designers a cost advantage compared to balsa and structural foam. The fiber-reinforced pre-form core is designed for vacuum infusion. It is comprised of fiberglass webs which develop nearly allthe core’s mechanical properties upon infusing and helps prevent resin race tracking even in contoured shapes. Fine cell foam minimizes excess resin absorption and provides durability during handling and processing.

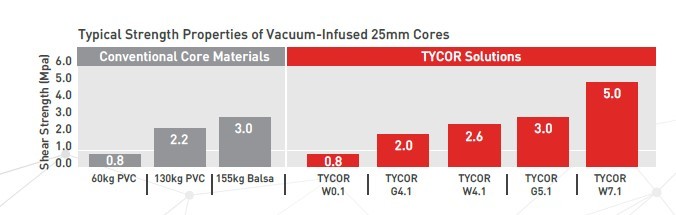

TYCOR® engineered core materials optimize weight, stiffness and strength in infused applications enabling structures that can be made lighter, less expesively and more reliably than old generation core materials.

Lower Weight

Infused TYCOR cores are significantly lighter than infused contourable coated balsa. The unique fiber architecture of TYCOR, combined with the closed cell low density foam, significantly reduce resin absorption in moded parts.

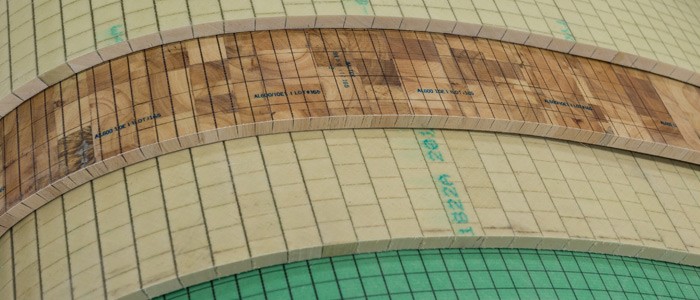

Breadth of Core Solutions

The TYCOR fiber-reinforced core family of products can be produced in a wide range of thicknesses from 12 mm to 100 mm. These designs encompass an offering of balanced and unbalanced orthotropic products which provide solutions that minimize weight and costs.

Higher Quality Infusion

As an assembled core, TYCOR® has inherent permeability that provides an improved quality infusion.

The dry fiber webs help wick and control resin flow through the laminate and holds the resin where it is designed to

be, minimizing voids and dry spots.

• Resin flow is controlled by fibers in L-webs and T-webs*

• Permeability designed to limit the tendency to race track compared to open channels

• Webs draw resin to mold side effectively leading to full wet out

*Optional T-Web design available for TYCOR® W series only

TYCOR® products are engineered for demanding structural applications. Designed for closed molding, TYCOR cores employ through-thickness fiberglass webs in low-density foam and surface skin reinforcements. The fiberglass webs offer high compression and shear strength while the surface skin reinforcements offer excellent core-to-skin bond for improved thoughness and durability.

METYX® offers a reliable advantage, with meaningful products and solutions that optimize structured performance with TYCOR®. Tailoring (engineering) properties to design requirements maximizes savings in weight and cost in structural applications.

Marine Applications

TYCOR’s internal web structure creates a network of intersecting ‘bulkheads’ within infused panels. Each compartment is very small and filled with closed cell foam. If moisture enters a panel via surface laminate damage or improper installation of a thru-hull fitting, penetration is limited to the compartments immediately adjacent to the damage or fitting. TYCOR panels have been fully submerged for years with little or no weight gain.

• Tank Walls

• Fish Ladders

• Submarine Camels

• Hulls and Decks

Other Proven Application

Industrial

• Tanks

• Containers

Infrastructure

• Bridge Decks

• Manhole Covers

• Utility Box Covers

Transportation

• Railcars

• Bus and Truck Floors

• Walls

Wind Energy

• Wind Blades